Ut can cadmiae mixture mori-cast partium auto partes minimize costs sine compromisando qualis?

21-11-2024 Minimizing costs sine compromising qualis est Zinc Mimey Die-Cast Auto Partibus involves pluribus opportuna accedit per vestibulum processus.

Design pro manibus: cursus consilio Auto partibus optimized pro mori, mittentes processus potest reducere materiam vastum, simpliciorem tooling, et minimize post-processus. Using Simple Geometries, Minimizing undercuts et vitandum universa features potest inferioris productio cost.Thin-Wall Design: Zinc Alloys potest consequi bona fortitudinem etiam tenuior muros. Cogitans partes tenuior moenia potest reducere materiam usus et pondus, triste et materiam costs et industria consummatio per mori, mittentem processus.

Pars consolidationis: combining multiplex components in unum mori-cast parte potest eliminate opus additional Conventus processus, reducendo labore et materia et frangi potius quam consuetudine, usura principalis initialis setup sumptibus, praesertim ad summus volumine productio.

Optimizing Alloy Compositionem: Dum Zinc Alloys offerre optimum perficientur, levi modifications ad alleo compositionem (ut per alloys cum inferioribus campester of sumptuosus elementa) potest reducere materiam sumptibus. Sed hoc oportet fieri diligenter ad vitare vires, corrosio resistentia vel essentialia proprietates.

Recycling FRAGMLING Material: RecivyCling Zinc Alloy FRAGMENTUM generatae per mori, mittentes processus potest reducere sumptus rudis materiae. Effecting effective exsequendam administratione ratio adjuvat minimize vastum et inferioribus opus recens mixta emseses.material fontem: acquirendi cadmiae Alloys in mole aut ex sumptus-efficientem potest reducere in materia sumptus per partem. Sumptus-effective supplementum censum renum rauci materiae et confert ad sumptus peculi.

Die-casting processum improvements: conflans in die-casting processus can amplio efficientiam. Usura magis precise temperatus controls, optimizing refrigerationem temporibus, et usus provectus technologiae sicut vacuo mori-casting potest amplio qualitas partium, reducere defectus, et crescere altiore.

Reducing exolvuntur tempus: brevians tempus capit ut proijicere potest crescere productio throughput et inferior laboris costs. This can be achieved through better process controls, faster cooling techniques, and optimized machine settings.Automating Post-Casting Operations: Automation of finishing processes, such as trimming, cleaning, or surface treatment, can lower labor costs and reduce errors that could lead to rework or scrapping.

Mors Vita Optimization: Extendens vitae formas et instrumenta potest reducere frequency et sumptus de fumere supplementum aut reparationibus. Hoc potest effectum eligendo ius instrumentum materiae, maintaining formae proprie et optimizing mori, mittentem processus ad minimize gerunt et lacrimam.

Minimum-sumptus fingunt materials: usura sumptus-effective materiae ad formam, quae sunt usque ad durandum satis ad requiritur productio fugit potest reducere tooling costs. Praeterea, quidam fabrica explorare modular tooling systems, ubi components de fingunt potest reponi singuli ut opus, quam tota Mold.optimizing Format refrigerationem et calefacit, bene administrandi et altum et calefacere sine necessario oving et costs.

Productio macilentum, exsequendam innitatur principia principia adiuvat minimize desertum, redigendum excessus inventory et streamline productio. Techniques such as just-in-time inventory, value stream mapping, and continuous improvement can identify and eliminate inefficiencies throughout the production process.Reducing Scrap Rates: Improving the consistency and accuracy of the die-casting process can reduce the rate of defective parts, which in turn lowers waste and the need for rework. Hoc potest esse effectum per circumsedere in melius apparatus calibration, processu magna et qualitas imperium menses.

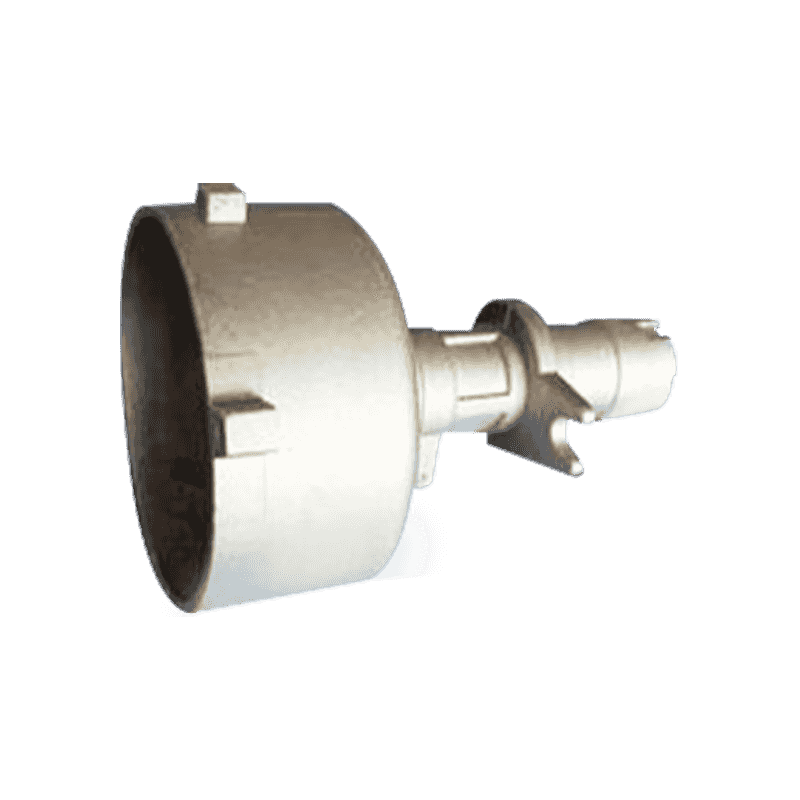

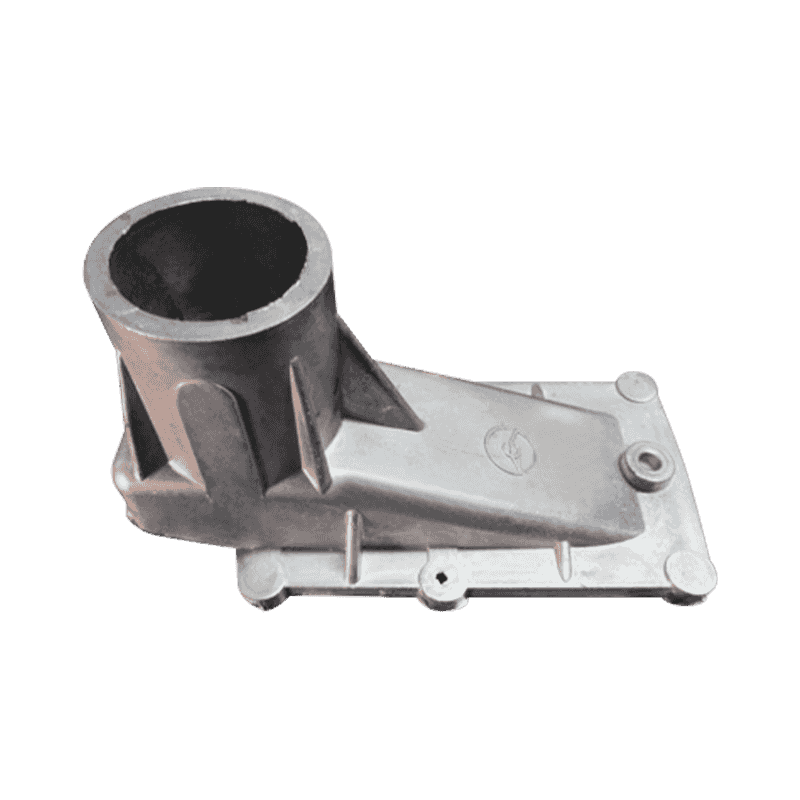

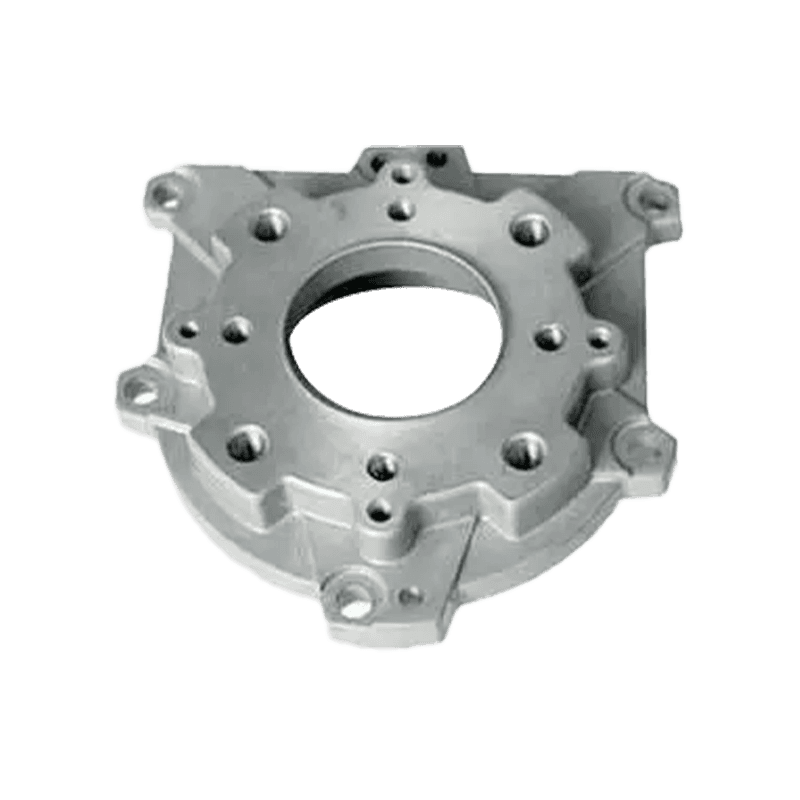

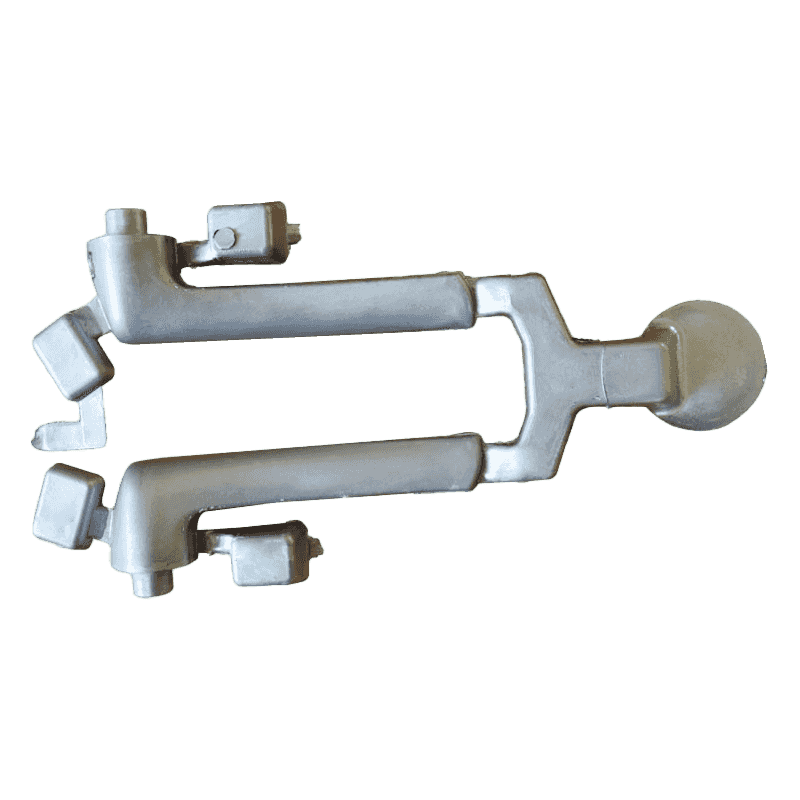

Tu es interested in products

Relinquere nomen tuum et inscriptio ad adepto nostrum prices et singula statim.